TECHNOLOGY

TECHNOLOGY

TECHNOLOGY

In our polyester plant, with its 1300 tons per month production capacity, we provide fastest shipment service. Besides, with online quality control system, long lots are produced and whole process is continuously followed so that stabilization in yarn quality is being guaranteed.

Textured - Melted - Elastane

TECHNOLOGY

We have integrated our quality starting from the production of raw materials by an investment of POY production with 10 tons per day capacity.

Ecru - Black - ColoredWe are making 5.500.000 m annual production with 600 looms in our

weaving plant in which perfectly produced indigo yarns turn into high quality fabrics.

In our plants, we are processing 100% cotton, polyester, viscose, tencel, linen,

polyamide, sustans, pbt, emana fibers and their blends with elastane/without elastane.

We are referring the products that are process controlled to finishing and quality control plant which we see as the heart of denim. Washing to quality control, in all finishing processes, we are showing our difference as quality human resource, technological superiority, and high environmental awareness.

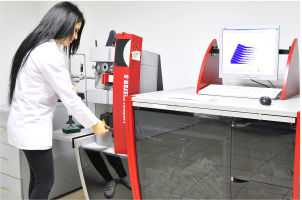

In our denim laboratory, not only are we measuring the value and analysis of our fabrics, but we are also writing the rules of innovation with our engineers, designers, and fashion experience management team. Principles of fashion trends and expectations, consumption habits, consumption preferences, innovation, functionality are turned into daily two new products in order to service denim sector via us.